Ivan Turbinca

Well-Known Member

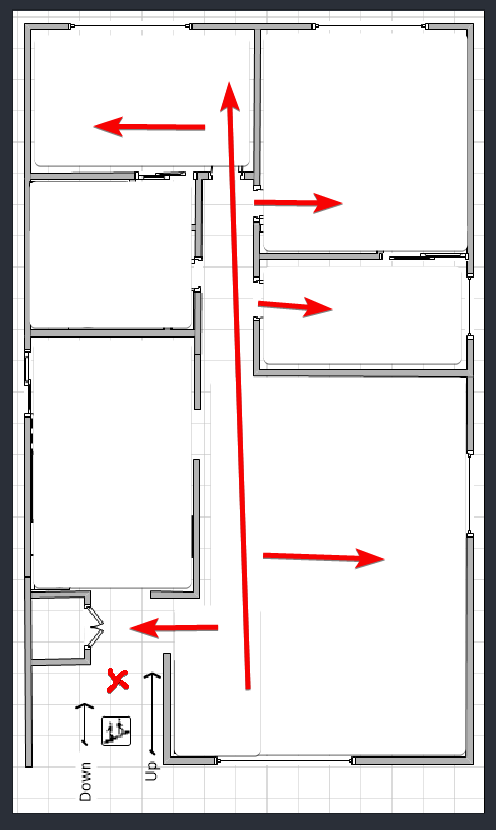

I am having a hard time with the engineered hardwood floor retailer that sold me the hardwood floor that is being installed next week

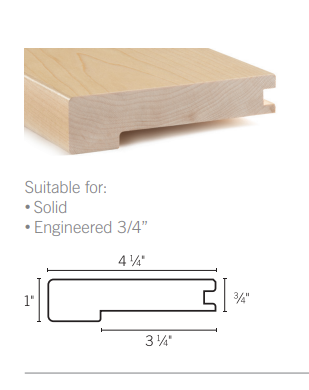

I tried to order a manufacturer made square bullnose piece and I was paying through my nose for it, 180CAD for 96" and needed like three to start with and I was going to order more. They missed the ball and they did not place the order so now the installer will start next week and he will need at least one of these.

I am now watching videos on YouTube about how to do this and I am seeing two things:

-they make the square bullnose from the same hardwood floor material by cutting 45" edges

-the above 45" edges are put together using nails

Here is the process

My questions:

-those 45" cuts will never be perfect and they present higher chances to wear off on the exposed edge where the stair user walks on -how do avoid this?

-they seem to use lots of nails and carpenter (?) glue to put them together -aren't those nail holes visible (

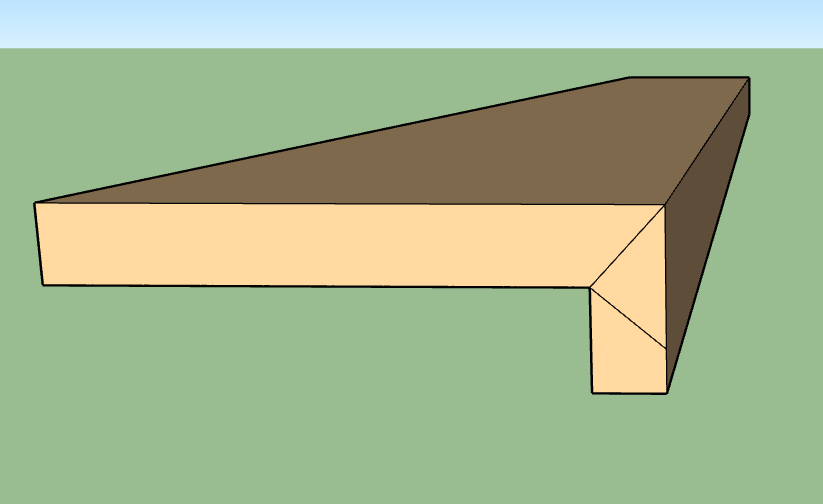

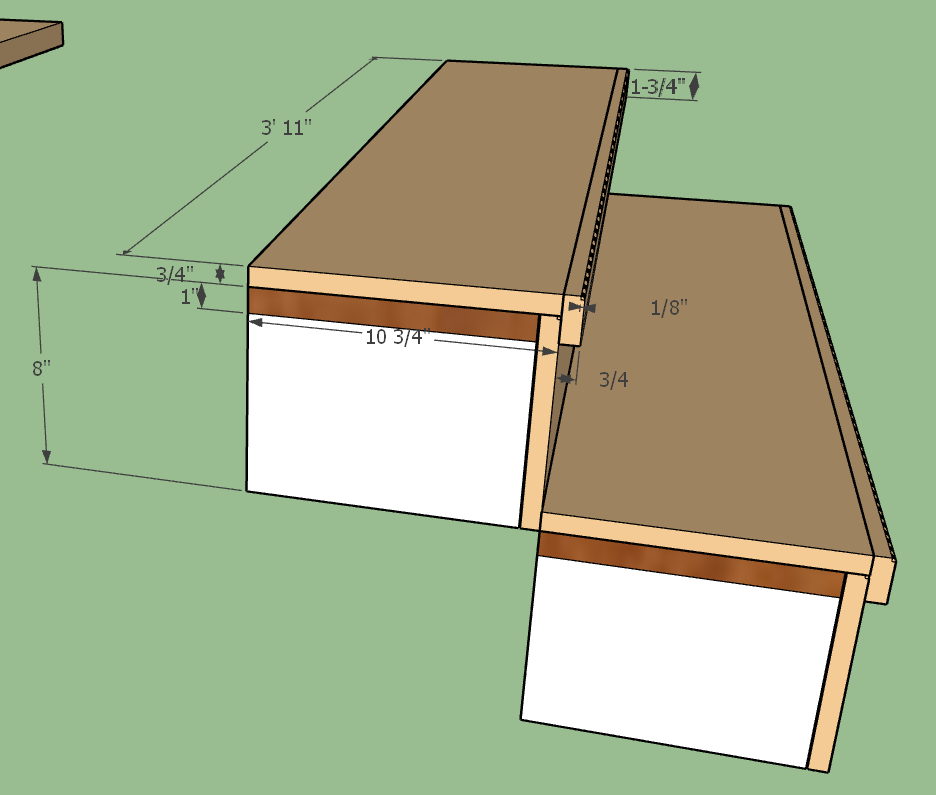

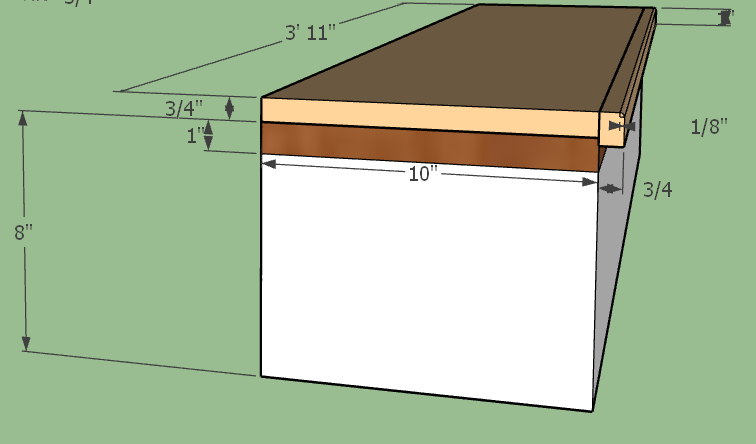

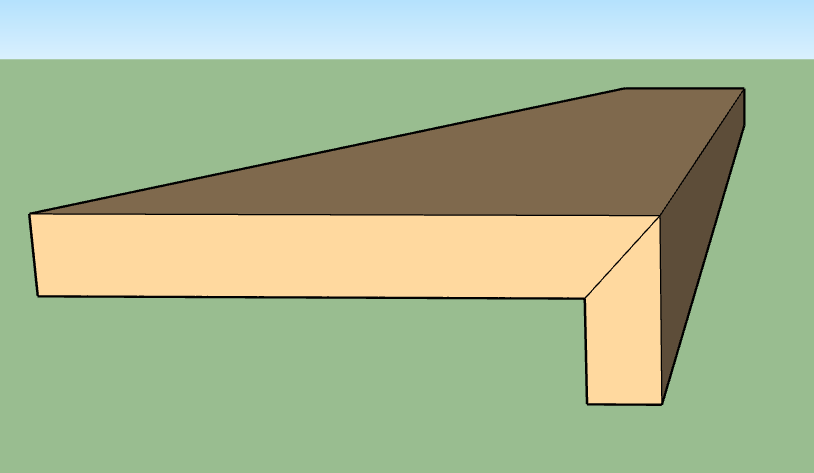

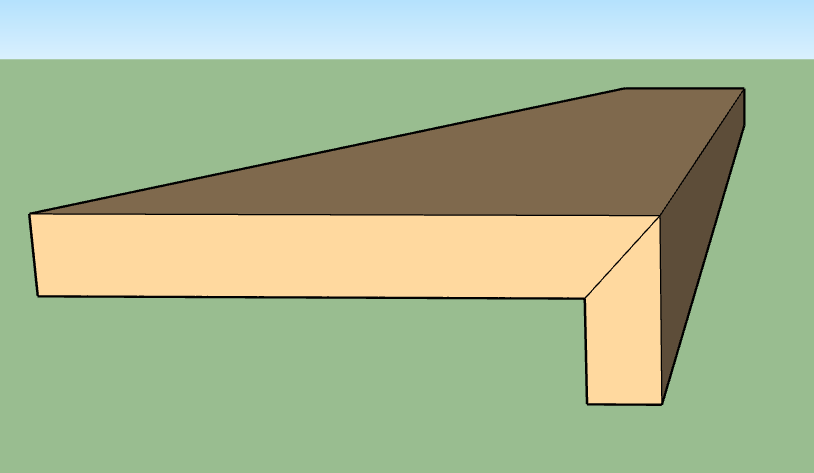

I think they build something like this

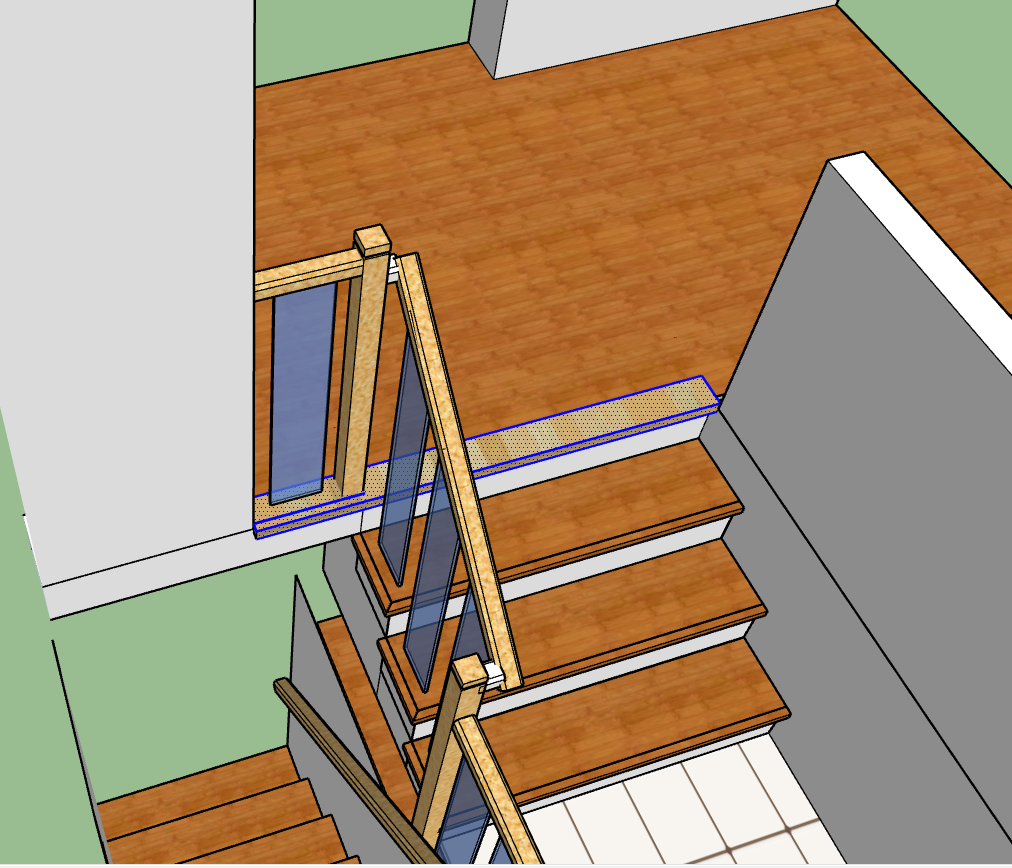

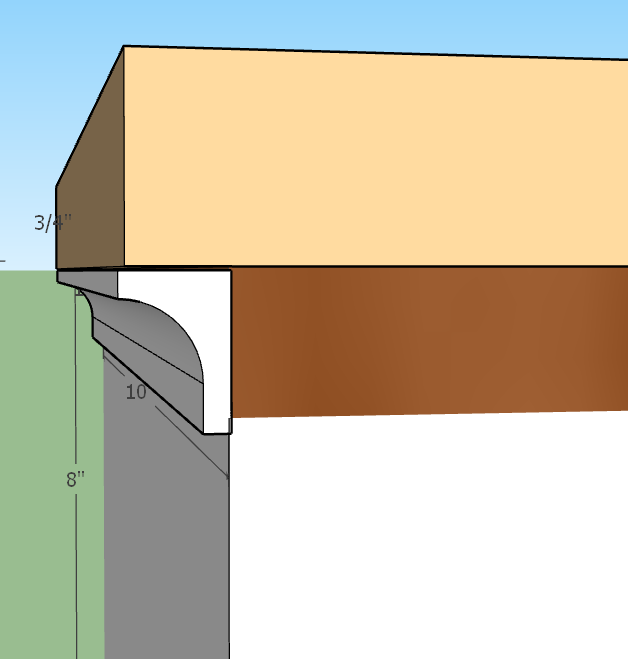

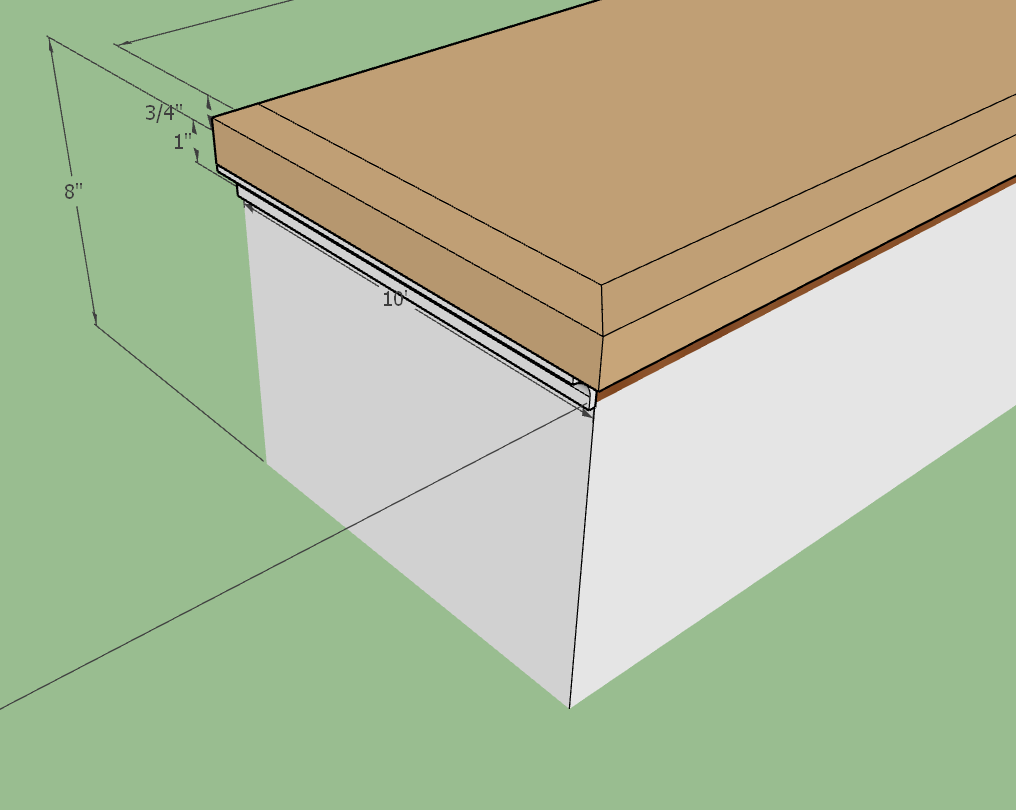

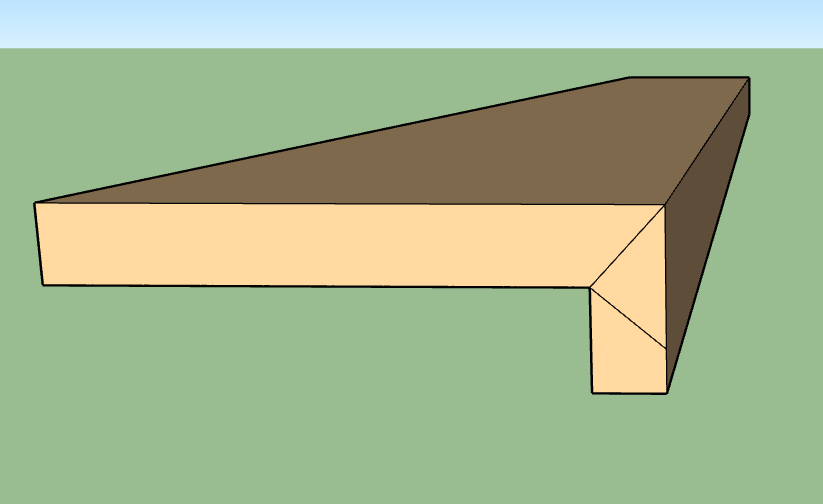

or like this

I tried to order a manufacturer made square bullnose piece and I was paying through my nose for it, 180CAD for 96" and needed like three to start with and I was going to order more. They missed the ball and they did not place the order so now the installer will start next week and he will need at least one of these.

I am now watching videos on YouTube about how to do this and I am seeing two things:

-they make the square bullnose from the same hardwood floor material by cutting 45" edges

-the above 45" edges are put together using nails

Here is the process

My questions:

-those 45" cuts will never be perfect and they present higher chances to wear off on the exposed edge where the stair user walks on -how do avoid this?

-they seem to use lots of nails and carpenter (?) glue to put them together -aren't those nail holes visible (

I think they build something like this

or like this