You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What did you do today?

- Thread starter havasu

- Start date

Help Support Flooring Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

We are at $6.50 per yard for the installation

$2 a yard for rip up

$15 per piece of furniture

And $8 per step plus this one head spindles to turn up two so that was another $60.

All said it was about an $1800 job for two days which isn’t horrible for doing carpet.

$2 a yard for rip up

$15 per piece of furniture

And $8 per step plus this one head spindles to turn up two so that was another $60.

All said it was about an $1800 job for two days which isn’t horrible for doing carpet.

Not at all. My goal is $900/day but I usually come up short. I have found that I am around 40 to 50 yards a day. That's part of my problem but I refuse to kill myself to make ends meet and save someone else a few bucks. I'm totally fine with staying home if my rate is more than the client wants to spend. The way I see it, if I'm going to break even or lose money, I don't want to be on a job. I'll go clean my office or trailer, meet with business partners, or do research on something instead of punishing my body. No employees or company debt helps.

All I did the last few years I worked was some apts with drop rooms. I could do the 40 yard one with one 3 ' seam in 90 minutes. Made $4 a yard. Good money in those days.

No, that would make it a LOT easier because I'd just say go find somebody else.Could be worse. Could have a bullnose that has to be wrapped through all those spindles… I remember in the 70s getting paid 50 cents a yard for rip ups ( no extra for steps) $2.50 a step to install if they were capped, closed steps were free… Stringers were a dollar a foot…Boy was I a stupid kid…

I guess the customer is coming into the store tomorrow to get a price on materials and installation.

I told the store owner that I need to see a piece of this carpet, a black and white photocopy doesn't tell me much about how hard this carpet will be to install.

All I know is it's a Godfrey Hirst woven wool carpet called Brookhaven III and it's a textured loop.

I don't know if this is stiff as formica or something installer friendly. That's why I want to hold a piece in my hands.

Attachments

Yeesh. That was some ugly carpet. LOL. I've seen uglier, but I don't blame people for pulling it up. Looked in good shape for that age though.

I bet my flooring installers were happy that I took out most of the carpet before they did their installations. I couldn't get the carpet in the living room because it was wedged under something, but I got it mostly pulled up.

Woke up sweating and noticed the sweat smelled like I hadn't taken my thyroid meds but I know I did. So, I think I might need a higher dose. There's a distinctive smell to the sweat when its a thyroid issue. Might explain why I'm so tired. I slept almost all day yesterday.

Had to get up early to go try to fix the water trough situation-- last night I discovered the hose was detached from the spigot & trough was empty (but still damp). Got up and checked the spigot-- works. Reconnected the hose and turned the spigot back on-- nothing came out. I decided to get a new filler bc the old one lasted over a decade. Waited for TSC to open and got a new valve and hose (old hose was stuck to the other filler).

My brother helped by reading the instructions and getting some cotter pins put in (I couldn't see the holes or make out the writing bc I can't find my reading glasses). He went inside while I dumped the muck out of the trough, took off the old valve, and put the new one on. I'd put out sweet feed to distract the cows but they got thirsty. Fortunately, Kwai didn't poke at me with her horns or bump into me this time (sometimes she does that when she gets impatient about food). She just started at me stupidly as I tightened the bolts on the clamps and set the trough back in place (I was lazy so I turned it up on its side so I wouldn't have to bend as far). Hooked it up, turned it on, and it started filling. I'm happy and the cows are happy.

There's a thunderstorm outside so I got it done just in time.

I bet my flooring installers were happy that I took out most of the carpet before they did their installations. I couldn't get the carpet in the living room because it was wedged under something, but I got it mostly pulled up.

Woke up sweating and noticed the sweat smelled like I hadn't taken my thyroid meds but I know I did. So, I think I might need a higher dose. There's a distinctive smell to the sweat when its a thyroid issue. Might explain why I'm so tired. I slept almost all day yesterday.

Had to get up early to go try to fix the water trough situation-- last night I discovered the hose was detached from the spigot & trough was empty (but still damp). Got up and checked the spigot-- works. Reconnected the hose and turned the spigot back on-- nothing came out. I decided to get a new filler bc the old one lasted over a decade. Waited for TSC to open and got a new valve and hose (old hose was stuck to the other filler).

My brother helped by reading the instructions and getting some cotter pins put in (I couldn't see the holes or make out the writing bc I can't find my reading glasses). He went inside while I dumped the muck out of the trough, took off the old valve, and put the new one on. I'd put out sweet feed to distract the cows but they got thirsty. Fortunately, Kwai didn't poke at me with her horns or bump into me this time (sometimes she does that when she gets impatient about food). She just started at me stupidly as I tightened the bolts on the clamps and set the trough back in place (I was lazy so I turned it up on its side so I wouldn't have to bend as far). Hooked it up, turned it on, and it started filling. I'm happy and the cows are happy.

There's a thunderstorm outside so I got it done just in time.

$13.74 ($0.21 / Fl Oz)

Armstrong Flooring 00325806 S-325 New Beginning Extra-Strength Stripper-1/2 Gallon Flooring Cleaner, Clear, 64 Fl Oz

Amazon.com

$12.98 ($3.24 / Fl Oz)

Zep Industrial Hardwood and Laminate Floor Cleaner - 1 Gallon - ZUHLF128 - Removes Spots, Stains and Scuffs. Cleans and Restores Shine

Amazon.com

$64.99 ($0.32 / Sq Ft)

$69.99 ($0.35 / Sq Ft)

FLOORLOT BlueStep Underlayment with Moisture Barrier for Laminate and Wood Floors, (200 sq.ft Roll)

Floorlot LLC

![MORE Luxury Vinyl Floor Cleaner for Vinyl Plank Flooring - Ready to Use, Daily Cleaning Formula for Tile, Vinyl Surfaces [Gallon / 128oz]](https://m.media-amazon.com/images/I/413LZHZiqCL._SL500_.jpg)

$44.99 ($0.35 / Fl Oz)

MORE Luxury Vinyl Floor Cleaner for Vinyl Plank Flooring - Ready to Use, Daily Cleaning Formula for Tile, Vinyl Surfaces [Gallon / 128oz]

MORE Surface Care

$17.99 ($0.14 / Fl Oz)

Rejuvenate Luxury Vinyl Floor Cleaner Gently Cleans And Revitalizes Luxury Vinyl Floors, 1 Gallon

Amazon.com

$12.98 ($0.10 / Fl Oz)

$18.03 ($0.14 / Fl Oz)

ZEP Ready-to-Use Hardwood and Laminate Floor Cleaner, Clear

Amazon.com

$26.99

$31.99

Goldblatt Trim Puller, Removal Multi-Tool for Commercial Work, Baseboard, Molding, Siding and Flooring Removal, Remodeling

GreatStar Tools

kwfloors

Well-Known Member

You should work here. We start at $13 yd. Most of what I do I'm at $15 yd.We are at $6.50 per yard for the installation

$2 a yard for rip up

$15 per piece of furniture

And $8 per step plus this one head spindles to turn up two so that was another $60.

All said it was about an $1800 job for two days which isn’t horrible for doing carpet.

My blades needed some love today. I have to label my 7.25” blades so I know which one is good and which one is not.

10” table saw blade needed cleaning. Hot soapy water and a scrub brush takes care of that.

I use a blade dampener on my table saw. Anyone else? Does it even matter? I think it does.

10” table saw blade needed cleaning. Hot soapy water and a scrub brush takes care of that.

I use a blade dampener on my table saw. Anyone else? Does it even matter? I think it does.

That’s good money!You should work here. We start at $13 yd. Most of what I do I'm at $15 yd.

I do as little carpet as possible.

I would rather plop down floating plank for $18/ yard.

What kind of fence do you have? I have a Beisenmeyer.My blades needed some love today. I have to label my 7.25” blades so I know which one is good and which one is not.

10” table saw blade needed cleaning. Hot soapy water and a scrub brush takes care of that.

I use a blade dampener on my table saw. Anyone else? Does it even matter? I think it does.

View attachment 15041View attachment 15038View attachment 15039View attachment 15037View attachment 15040

I’ve got a Rousseau table saw stand for my Dewalt job site saw. The rip fence works great but it’s definitely no Biesemeyer. I have to set up and break down my equipment at different job sites too often and I’m sure I would bung up an expensive fence.

My table saw is a Craftsman cabinet saw. Gave $1200 for it about 15 years ago. Seldom use it now. Wood is too high to build much. I have a decent wood shop. 2 band saws, 3 scroll saws, planer, jointer, spindle sander, stand sander, router table, drill press, lots of hand tools. But they mostly just sit anymore. Can't really see good enough to do scroll saw work.

At one time I built furniture and made Christmas ornaments. Also rocking horses and rocking dinosaurs. Kids toys.

At one time I built furniture and made Christmas ornaments. Also rocking horses and rocking dinosaurs. Kids toys.

Last edited:

Gas is $3.94

My table saw is a Craftsman cabinet saw. Gave $1200 for it about 15 years ago. Seldom use it now. Wood is too high to build much. I have a decent wood shop. 2 band saws, 3 scroll saws, planer, jointer, spindle sander, stand sander, router table, drill press, lots of hand tools. But they mostly just sit anymore. Can't really see good enough to do scroll saw work.

At one time I built furniture and made Christmas ornaments. Also rocking horses and rocking dinosaurs. Kids toys.

Sounds like you have quite the set up. Are your grandkids interested in woodworking?

Not really. My 17 year old grandson is working 40 hours a week and going to college. He wanted to be a welder but would need to borrow $16,000 to do it. I no longer have a welder or I could get him started. He got all his Eagle scout badges done only to find out that his scoutmaster had turned nothing in. He is pissed.Sounds like you have quite the set up. Are your grandkids interested in woodworking?

Not really. My 17 year old grandson is working 40 hours a week and going to college. He wanted to be a welder but would need to borrow $16,000 to do it. I no longer have a welder or I could get him started. He got all his Eagle scout badges done only to find out that his scoutmaster had turned nothing in. He is pissed.

Sounds like the scout master needs to be stabbed in his ass cheek with a Swiss Army knife.

My buddy is a welder and he loves it. I think it’s boring. Any companies hiring in your area where your grandson can get some OTJ training? He might find out he doesn’t like it. Or he can get trained while getting paid and not come out of school buried in debt.

You can get a 110 volt welder from Harbor Freight for maybe $800. Move some of your wood working equipment around and set up a practice space in your shop for him to play around with the welder. If nothing else he can weld up yard art. That **** is expensive for what it is.

I never would have thought to wash the blades? Learn something new every day!

Pitch and resin builds up on the blade and adds resistance. They have blade cleaner but some good ol hot soapy water works just fine. You’ll get a lot longer life out of your blades if you clean them regularly.

You got a bench top planer? Same thing happens with pitch and resin building up on the bed and rollers so those need to be cleaned as well. I wax the bed of my planer with some good ol turtle wax after I clean it. I bet you could wax your saw blades as well for the same reason but I’ve never gone that far… yet.

Last edited:

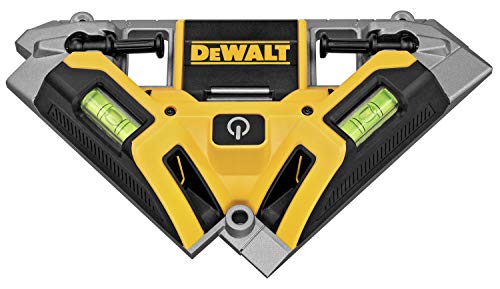

I spot the “Jig Pro”

Similar threads

- Replies

- 13

- Views

- 4K