Now the weather has been too cold and we had some pipes freeze. Waiting for spring I guess, but in the meantime, I want to get a supply list together.

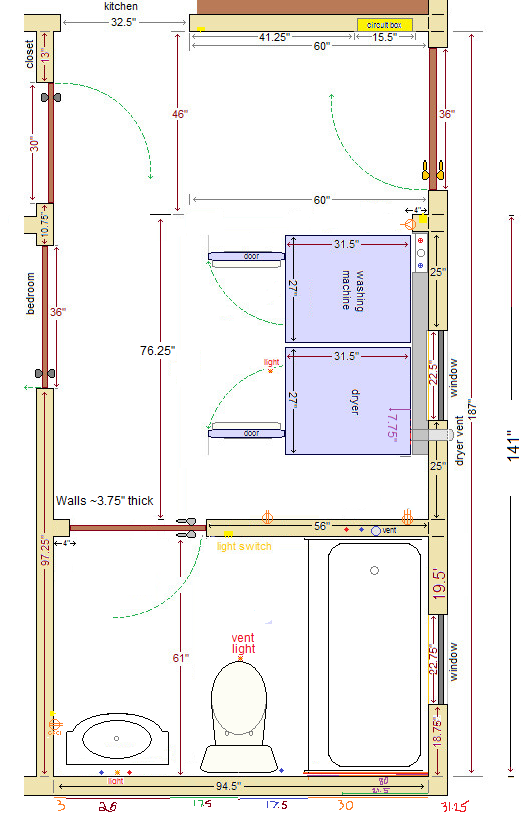

This is my latest sketch of the revisions I plan to make to the current layout (knocking down some non-load bearing walls).

By my math, if I took down the two walls plus the one between the laundry room and bathroom (temporarily) while working on the floor, I should be able to re-do it with either four 8x4 sheets or eight 4x4 sheets (I'm not forgetting I will have to double that but have half of them 3/4" and half 1/4"). I'll have to price them out and see which will give me the best bang for my $.

Since I don't expect there to be joists at all of the ends, I will want to add some extra ones to support edges near walls. I want to verify what size planks I will need. Should I go with 2x8 or 2x10? (I think the current joists are roughly spaced 24" apart). I was thinking, depending on how I do them, I could have 2x8s on the west (left) side but do 2x10s under where the washing machine and bathtub will be. What do you guys think?

Can I use drywall tape and spackle or something to smooth out seams so the floor will be smoother before I put down vinyl sheet?