I wonder if anybody makes a 45° saw blade with the bottom of the tooth being 3/8 in wide...You just dont make a V-Groove, just use a wider carbide tip and away you go. At the right depth, it works well, I fill the void with PL which I realize might not be the best idea but seeing as I only want it for a filler and it is up against wood, I am not too worried about plastercizers and the like. I was cutting them at angles, then I realized that took a long ass time and gave up on that seeing as there was no need

Jigs are the key to life!! The last set we did, man we boggled up a few trying to get things set where we wanted them, but once you got it, you got it and dont bloody change anything or breath on the saw hard lol

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Up your game

- Thread starter highup

- Start date

Help Support Flooring Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Holy crap ask and ye shall receive.

(Not for use with portable table saws)

https://beavertools.com/rc-4300-ama...XWBDsRTjGxW-phe87nrfmjIThHeihctxoCkK0QAvD_BwE

(Not for use with portable table saws)

https://beavertools.com/rc-4300-ama...XWBDsRTjGxW-phe87nrfmjIThHeihctxoCkK0QAvD_BwE

Mark, when you make your stair noses what do you use to heat them up, the heat gun?

I'm going to do some for a friend this weekend & the video of this guy doing them looks like the process will take a lot of time. He took like 5 min heating an bending a 1' piece. Too much time for me on a 4' plank. Was thinking my torch and some mapp gas would speed it up some?

Or I have a nice mama bear wood stove in my shop. Maybe I can get that cranking and somehow use it to heat up one while cutting another. Lol. Sounds crazy but I am's what I am's.

I'm going to do some for a friend this weekend & the video of this guy doing them looks like the process will take a lot of time. He took like 5 min heating an bending a 1' piece. Too much time for me on a 4' plank. Was thinking my torch and some mapp gas would speed it up some?

Or I have a nice mama bear wood stove in my shop. Maybe I can get that cranking and somehow use it to heat up one while cutting another. Lol. Sounds crazy but I am's what I am's.

That right there made my day. I just use my leister and away I go. Fire+foam+clients=bad for me

Holy crap ask and ye shall receive.

(Not for use with portable table saws)

https://beavertools.com/rc-4300-ama...XWBDsRTjGxW-phe87nrfmjIThHeihctxoCkK0QAvD_BwE

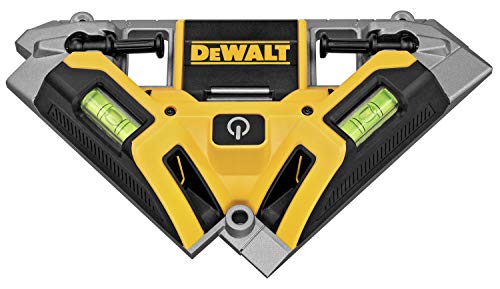

I believe the Dewalt 7491 will accept a dado blade but for $200 I’m buyin a router bit.

No way man, that thing right there is the bees knees. I am going to order one. First job, paid for and it would last forever. Mmmmmm stuff!!

Router is messy and frankly scares the living **** out of me. I will use anything that is not a router as often as possible lol

Router is messy and frankly scares the living **** out of me. I will use anything that is not a router as often as possible lol

$17.99 ($0.14 / Fl Oz)

Rejuvenate Luxury Vinyl Floor Cleaner Gently Cleans And Revitalizes Luxury Vinyl Floors, 1 Gallon

Amazon.com

$26.99

$31.99

Goldblatt Trim Puller, Removal Multi-Tool for Commercial Work, Baseboard, Molding, Siding and Flooring Removal, Remodeling

GreatStar Tools

$64.99 ($0.32 / Sq Ft)

$69.99 ($0.35 / Sq Ft)

FLOORLOT BlueStep Underlayment with Moisture Barrier for Laminate and Wood Floors, (200 sq.ft Roll)

Floorlot LLC

![MORE Luxury Vinyl Floor Cleaner for Vinyl Plank Flooring - Ready to Use, Daily Cleaning Formula for Tile, Vinyl Surfaces [Gallon / 128oz]](https://m.media-amazon.com/images/I/413LZHZiqCL._SL500_.jpg)

$44.99 ($0.35 / Fl Oz)

MORE Luxury Vinyl Floor Cleaner for Vinyl Plank Flooring - Ready to Use, Daily Cleaning Formula for Tile, Vinyl Surfaces [Gallon / 128oz]

MORE Surface Care

$12.98 ($0.10 / Fl Oz)

$18.03 ($0.14 / Fl Oz)

ZEP Ready-to-Use Hardwood and Laminate Floor Cleaner, Clear

Amazon.com

$12.98 ($3.24 / Fl Oz)

Zep Industrial Hardwood and Laminate Floor Cleaner - 1 Gallon - ZUHLF128 - Removes Spots, Stains and Scuffs. Cleans and Restores Shine

Amazon.com

$13.74 ($0.21 / Fl Oz)

Armstrong Flooring 00325806 S-325 New Beginning Extra-Strength Stripper-1/2 Gallon Flooring Cleaner, Clear, 64 Fl Oz

Amazon.com

That’s why you need a router table. Doesn’t want to wander as much

I have a table.... I think its the noise lol. Sounds scary

That blade scares the crap out of me. That looks like bad things could happen fast. I don't know why. I think I'd want to have a power feed attachment so I wouldn't have to get my hands or my body anywhere near the son of a b****No way man, that thing right there is the bees knees. I am going to order one. First job, paid for and it would last forever. Mmmmmm stuff!!

Router is messy and frankly scares the living **** out of me. I will use anything that is not a router as often as possible lol

Can you imagine using that and having it grab a piece of material and throw it through the wall into the street?

Actually the price surprised the hell out of me especially being an Amanna product.

Before ordering, you ought to call their tech line and ask why they don't want it being used on portable table saws.

It would be nice to hear their reasoning. Maybe there's a good reason or maybe they simply don't want it installed on a $110 harbor freight model.

Table saws are direct drive and probably less rigid than a shop saw. Maybe that's why.

That's what hearing protection is for you silly goof.I have a table.... I think its the noise lol. Sounds scary

No I don't use it as much as I should, but if I do an intricate cut with a jigsaw, I feel more relaxed and better able to concentrate with the hearing protection on. It makes a lot of difference without the distraction of the noise.

I have a table.... I think its the noise lol. Sounds scary

What?? You never clamped down a fidget spinner and got it going super sonic speed with your air compressor?

I never owned a fidget spinner I've seen videos. Cleetus McFarland comes to mind.

...well that does it, my newer Makita compressor goes up to 140 so you know I'm going to have to buy one now.

..... And I still have an older non OSHA approved air nozzle.

...well that does it, my newer Makita compressor goes up to 140 so you know I'm going to have to buy one now.

..... And I still have an older non OSHA approved air nozzle.

No reason not to have a tachometer on this sucker.

These are the ones I get when I send them out to be done. They look sharp and I'm thinking I could make a jig out of some conduit or iron pipe etc.

They just cut a few relief cuts on a table saw, heat and bend it looks like? When I finally get some down time I'll have to give it a goView attachment 13340View attachment 13341

I like the bullnose look. Those look really good all one piece.

I'd love to see a cross section. I'd also like to see how thin their saw curf is. You can't make something round with three or four saw cuts.These are the ones I get when I send them out to be done. They look sharp and I'm thinking I could make a jig out of some conduit or iron pipe etc.

They just cut a few relief cuts on a table saw, heat and bend it looks like? When I finally get some down time I'll have to give it a goView attachment 13340View attachment 13341

I would also think that the voids in any cuts regardless would need to be filled with epoxy or something otherwise it's just a wear layer holding the entire thing together.

I'm going to have to get a couple pieces of flooring and play with it.

That looks like fun

That looks like fun

Those are beyond my talent level.These are the ones I get when I send them out to be done. They look sharp and I'm thinking I could make a jig out of some conduit or iron pipe etc.

They just cut a few relief cuts on a table saw, heat and bend it looks like? When I finally get some down time I'll have to give it a goView attachment 13340View attachment 13341

I still have one more of these to finish and wood is so high, I am done.

No they aren't. It really is simple when you boil it down. Just a matter of getting in there. You would be fine.Those are beyond my talent level.

Similar threads

- Replies

- 22

- Views

- 4K

- Replies

- 0

- Views

- 966